Government's Role

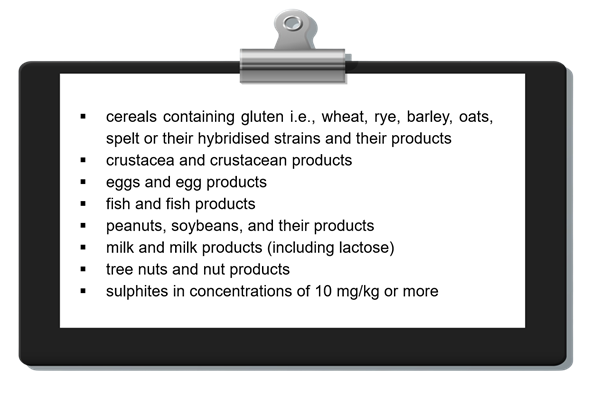

To protect those with food allergies, the Singapore Food Agency (SFA) enforces regulations requiring companies to list ingredients on prepacked foods. Under the Singapore Food Regulations, prepacked food products containing food and ingredients that are known to cause hypersensitivity must be declared on food packaging labels. The following known food allergens must be declared on food labels:

For more information on our labelling requirements, read our Labelling Guidelines for Food Importers and Manufacturers.

In addition, SFA adopts a science-based risk assessment and management approach that is consistent with international standards. SFA has in place a food safety regime that involves sampling and testing of food products sold in Singapore to ensure they meet our regulatory requirements, including whether there is presence of an undeclared allergen. Food that is not in compliance with SFA’s food safety requirements will not be allowed for sale in Singapore. When a breach of food safety requirements in food products is detected, SFA will conduct a thorough investigation on the implicated food product. The implicated products may also be recalled as a precautionary measure.

Industry's Role

Food safety is a joint responsibility shared between the Government, industry and consumers. To ensure consumers’ safety, the industry plays a vital role in ensuring that food allergens are managed throughout the entire food supply chain and production process. Cross-contamination can potentially occur at different stages of the supply chain, such as during the handling of ingredients, manufacturing of food products or even higher up in the food chain, such as during harvesting and transportation.

An effective allergen management programme should form part of a food manufacturer’s Good Manufacturing Practices (GMP). To eliminate cross-contact allergens, a company should also implement the Hazard Analysis Critical Control Point (HACCP), which is an internationally recognised science-based systematic approach to identify, evaluate, and control any biological, chemical, or physical hazards at each stage of the food supply chain.

The aim of HACCP is to ensure safe food is consistently being produced by manufacturers. Some recommended good practices that food manufacturers can adopt are highlighted below:

Sourcing of Ingredients

It is important for the industry to handle food ingredients in a way that prevents or minimises the presence of unintended allergens. Measures should be put in place to evaluate the presence of unwanted allergens in the ingredients before use. These can include consistently reviewing the list of suppliers to check that their practices and operations ensure there is no cross-contamination that introduces unwanted allergens. Suppliers themselves should also ensure they do the same when sourcing for ingredients.

Storage of Ingredients

Ingredients that contain allergens must be stored separately from those which do not contain allergens. Both should be properly labelled and physically segregated if stored in the same storage facility. If containers are used, the reuse of containers for non-allergenic ingredients should be avoided if they have already been used for allergenic ingredients.

Production Scheduling and Sanitation

Production schedules should be arranged such that products containing allergens do not contaminate non-allergen products. For example:

- Products containing allergens could be manufactured at the end of the day or shift.

- Products containing allergens could be manufactured consecutively to minimise changeovers.

- Allergenic ingredients could be added as far downstream as possible in the processing line to minimise the number of equipment that comes into contact with the allergen.

- Products containing allergens could be allocated to a separated production line. If the same production line is used, operators should implement a thorough sanitation programme in-between manufacturing processes to prevent cross-contamination.

An effective scheduling and sanitation programme not only prevents cross-contamination, but also saves sanitation costs and production downtime for manufacturers.

Food Contact Surfaces

To minimise cross-contamination, tools should be designed such that products or ingredients containing allergens do not get caught easily in machinery. For example, welds should be smooth, seals and hoses should not contain cracks, and “dead ends” in pipework or other areas where products can accumulate should be eliminated.

Cleaning Programme

For some, very small amounts of allergens can cause adverse reactions, such as anaphylactic shock. As such, it is important for the industry to carry out thorough cleaning of food contact surfaces to reduce the risks of allergen cross-contamination. For instance, ‘hard to reach’ areas should be dismantled and manually cleaned to ensure they are free from allergen residues.

Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. Procedures to check that cleaning practices are effective at removing allergens should also be in place, such as implementation of allergen residue swab testing of food contact surfaces after cleaning or allergen residue testing of Clean-in-place (CIP) rinse water.

Any spillage that occurs during processing, storage and transportation should be cleaned immediately to prevent subsequent cross-contamination.

Rework and Work-in-Process

Rework and Work-in-Process (WIP) that contains allergens should be stored in containers with secured covers in designated areas. The containers should be labelled clearly with the types of allergen present. It is important to have proper inventories to prevent or minimise the potential for incorporation into the wrong product.

Employee Training

Employees involved in handling ingredients, equipment, utensils, packaging, and final products must undergo proper training. Manufacturers should highlight to them their role in preventing allergen contamination and to urge staff to take immediate action if any risk of contamination is suspected. Employees should also be sent for training on a regular basis (e.g. refresher course) to reinforce behaviour.

Packaging Labelling

Under the Food Regulations, all ingredients and additives used in prepacked food must be declared in descending order of the proportion by weight in which they are present, under the statement of ingredients. It is also a requirement under the Food Regulations to declare the presence of ingredients that may cause hypersensitivity to individuals, under the statement of ingredients for pre-packed food products. This would include the declaration of the following food and ingredients in prepacked food products:

| i |

Cereals containing gluten |

This group includes wheat, rye, barley, oats, spelt or their hybridised strains and their products. |

| ii |

Crustacean and crustacean products |

This group includes crayfish, prawns, shrimps, lobsters, crabs and their products. |

| iii |

Eggs and egg products |

This group includes eggs from laying hens as well as eggs from duck, turkey, quail, goose, gull, guinea fowl and their products. |

| iv |

Fish and fish products |

This group also includes fish and molluscs such as oysters, clams, scallops and their products. |

| v |

Peanuts, soybeans and their products |

Peanuts may be declared using similar terms such as “groundnuts”. Terms such as “soya” or “soy” can be used for soybeans. |

| vi |

Milk and milk products (including lactose) |

This group includes milk from cows, buffaloes, or goats and their products. |

| vii |

Tree nuts and nut products |

This group includes almond, hazelnut, walnut, cashew nut, pecan nut, Brazil nut, pistachio nut, macadamia nut and their products. |

| viii |

Sulphites in concentrates of 10mg/kg or more |

Food products that have sulphur dioxide and/or sulphites directly added and/or carried over from food ingredients at a total concentration of 10mg/kg or more (calculated in terms of total sulphur dioxide).

|

Alternatively, ingredients that may cause hypersensitivity to individuals may be listed under statements like “Allergy information” or “Contain”. However, these statements should not be used as a means to declare additional food ingredients/additives which are not declared in the statement of ingredients.

The Food Regulations do not require ingredients that are known to cause hypersensitivity to individuals to be specially highlighted (e.g. in a separate statement or in bold text) if these ingredients have been clearly declared under the statement of ingredients. For example, if the ingredient, cuttlefish, is already declared under the ingredient listing, it would not be necessary to include an additional statement such as “Contains fish” to highlight the presence of cuttlefish in the product.

The requirement to declare the presence of ingredients that may cause hypersensitivity to individuals does not apply to those that are unintentionally introduced into foods such as through contamination from such ingredients during manufacturing, transportation, storage or any other means. Please refer to The Use of Precautionary Allergen Labelling for more information on what food manufacturers can do to protect the allergenic community from the unintentional introduction of ingredients that may cause hypersensitivity.

Monitoring and Review

For effective monitoring and review, food manufacturers must identify the key employees involved and ensure adequate documentation. The allergen management programme should be monitored and reviewed periodically via audits so that i) any weaknesses can be detected, and corrective actions can be taken and ii) there is assurance that the procedures remain relevant and updated.

With these best practices in place, food manufacturers can ensure safe products for allergenic consumers.